GREEN & COOL lead the way with CO2 technology replacing NH3

SWEDEN – A small community in Sweden will forever reside in the history books as home to the first ice rink in Europe to be cooled entirely using CO2 technology, via GREEN & COOL’s Mistral unit.

In 2013, in the town of Gimo, Sweden, located about 120 km north of Stockholm, the roof of the local ice arena collapsed, leaving the city without an ice rink. Fortunately for local sports lovers and children, this situation only lasted a short time before a solution was found.

In 2014, the building was completely restored, resplendent with a new ice rink and a special cooling system upgrade. GREEN & COOL supplied its transcritical CO2 Mistral unit, making Gimo’s rink the first ice rink in Europe to use pure CO2 technology.

CO2 transcritical cooling most efficient for ice rinks

Ice rinks consume a significant amount of energy, with the average use of a Swedish rink equating to about 1,000 MWh per year. As a rule, the refrigeration system, which generally operates with a cooling capacity of around 300-350 kW, is the main contributor, using about 43% of the total energy consumed.

Until 2011, almost all Swedish rinks used ammonia/brine systems and even today, those employing the CO2 system only use the refrigerant in the secondary cycle instead of brine.

CO2 has become a successful refrigerant in the food distribution industry, and now has the potential to revolutionize the ice rink industry.

A Swedish study compared three ice rink refrigeration systems, one an entirely CO2 system, another combining NH3 and CO2 and the last combining NH3 and brine and results showed that the application of CO2 technology is the most efficient system with the lowest energy consumption while, regarding heat recovery potential, the CO2 system has higher energy savings compared to the other systems.

The Mistral system : an innovation for ice rinks

GREEN & COOL supplied its Mistral system to the Gimo rink, while the system was delivered and installed by INDUSTRY & LABORATORIEKYL. By working together, companies have resolved oil handling problems, allowing CO2 systems to be used in arenas. The companies plan to launch a major marketing campaign which will include a website on ice rinks and CO2 refrigeration.

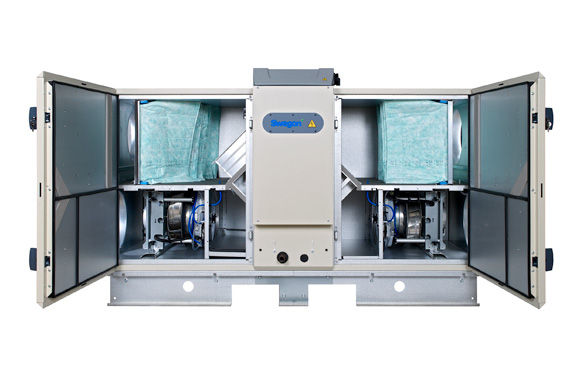

GREEN & COOL’s Mistral has a 250 kW cooling capacity and is capable of recovering most of the waste heat from the cooling process which can then be used for site heating and hot water. Excess heat is transferred to five 200-meters-deep drilled wells, which provide geothermal energy storage.

The Mistral unit is available in various sizes and configurations. It can be configured as a refrigeration unit, a freezer unit or an air-conditioning unit and can easily be upgraded with a heat exchanger on the warm side.

Certain technical specifications of the unit include:

- Single temperature range

- Indoor unit or outdoor with optional weather protected low noise panels

- High/medium/low temperature

- Swept volume high temperature: 1,12–159,42 m³/h

- Swept volume medium temperature: 1,12–159,42 m³/h

- Swept volume low temperature: 1,38–75,6 m³/h (for 6 compressors)

The growing buzz around GREEN & COOL

GREEN & COOL is a leading supplier of refrigeration systems using environmentally friendly CO2 (carbon dioxide) as a refrigerant and high quality components. The foundation of the company is based on the goal of two contractors to create a CO2 refrigeration system. They installed the first unit in a grocery store in 2003 and it was in 2007 that the brand GREEN & COOL was officially born.